It is unlikely you will encounter this standard in the process industries. The SAE Aerospace panel developed AS4059 specifically for aircraft hydraulic systems. To conform to any particular standard reference should be made to the recommended experimental procedure for hydraulic oil analysis and particle count test. Note - The comparisons relate to particle count data only.

Iso 4406 particle count chart iso#

See the NAS vs ISO cleanliness chart below for a good approximation. Inevitably, there is a requirement to be able to compare these cleanliness classification codes. See the NAS 1638 chart below for the various cleanliness levels:Ĭonverting Oil Cleanliness Standards - ISO to NAS to ISO NAS1638 is comprised of fluid cleanliness classes, each class defined in terms of maximum allowed particle counts per 100ml for designated particle size ranges. It is used widely in the UK North Sea industries. The NAS 1638 cleanliness standard was originally developed for aerospace components in the US but is still widely used for industrial and aerospace fluid power applications.

Iso 4406 particle count chart full#

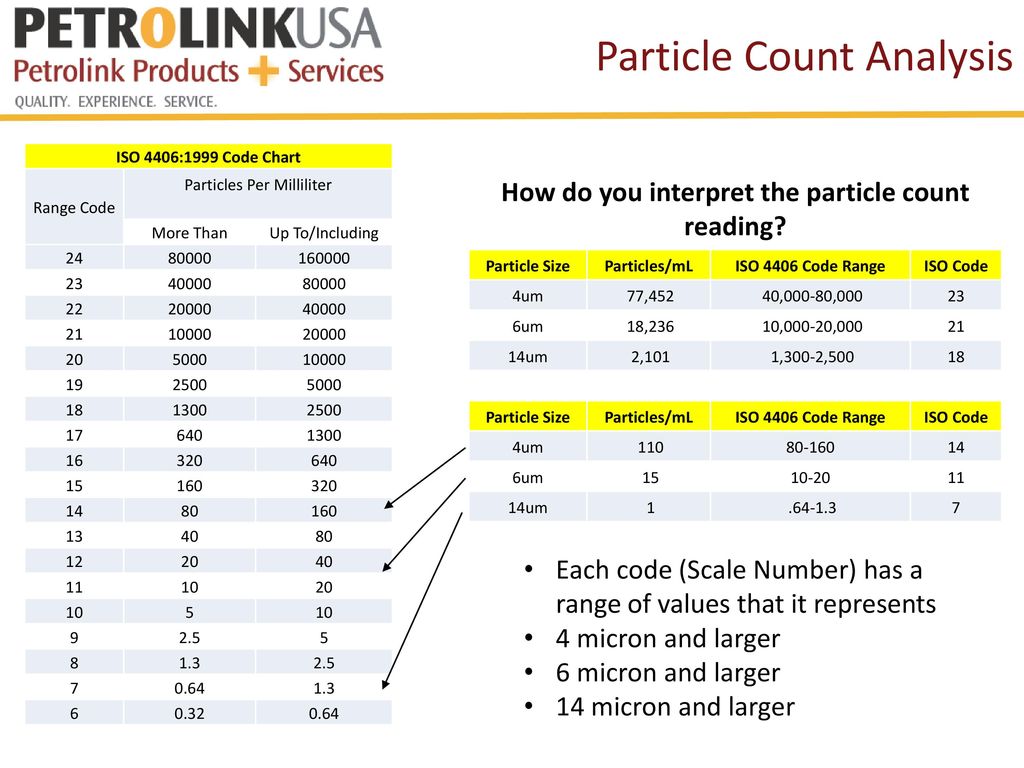

The full table of particle count ranges for the ISO cleanliness code is shown in the ISO 4406 chart below: Using the ISO particle count table below, we can see that an oil with a cleanliness rating of 18/16/13 would mean that it containedġ300 - 2500 particles greater than 2 micron in sizeģ20 - 640 particles greater than 5 micron in size, andĤ0 - 80 particles greater than 15 microns in size. However some manufacturers have expanded the code to three numbers by the addition of a code number representing the number of particles greater than 2 µm, e.g. ISO/FDIS 4406:2017(E) Number of particles per millilitre Scale number More than Up to and including 1,3 2,5 8 0,64 1,3 7 0,32 0,64 6 0,16 0,32 5 0,08 0,16 4 0,04 0,08 3 0,02 0,04 2 0,01 0,02 1 0,00 0,01 0 NOTE: Reproducibility below scale number 8 is affected by the actual number of particles counted in the fluid sample. 16/13, based on the number of particles greater than 5 µm and 15 µm respectively in a known volume of fluid. Under ISO 4406 cleanliness is classified by a two number code, e.g. The ISO Cleanliness Code, ISO 4406, 1987 is perhaps the most widely used International standard for representing the particle contamination level of industrial fluid power systems.

The two most likely to be encountered in the oil & gas, and process industries are The ISO Cleanliness Code (ISO 4406), and The NAS 1638 cleanliness standard.Īn introduction to each of these allowable particle contamination standards is provided below. Measuring hydraulic cleanliness is not straight forward, consequently various standards exist on this subject. What are the Standards for Hydraulic cleanliness? Therefore it is common to specify that the hydraulic fluid used in the system is cleaned to a measurable degree of cleanliness e.g. Clearing a blockage can be difficult, time consuming and very expensive, especially in subsea applications.

Integral to the actuator are components with small bores that can become blocked if the fluid has particles of debris within it. Hydraulic fluid is used as the motive power for many actuated valves, often in subsea applications. Why is Hydraulic Oil Cleanliness Important? A key parameter in determining the quality of your hydraulic oil is its cleanliness, or as it is sometimes refered to, the oil's particle count. Good quality hydraulic oil is essential in any hydraulic circuit.

0 kommentar(er)

0 kommentar(er)